(1) Multi-dimensional imaging

With the advancement of technology, optical imaging technology is also experiencing rapid development, and multi-dimensional imaging is becoming increasingly mature. In the field of machine vision, multi-dimensional imaging as an advanced technology can effectively improve image quality and capture useful information, reducing the difficulty of post-processing, and significantly enhancing detection accuracy and equipment reliability. It has been widely used in fields such as medical imaging, semiconductor manufacturing, and non-destructive testing. With the progress of the times, multi-dimensional imaging will be more widely used.

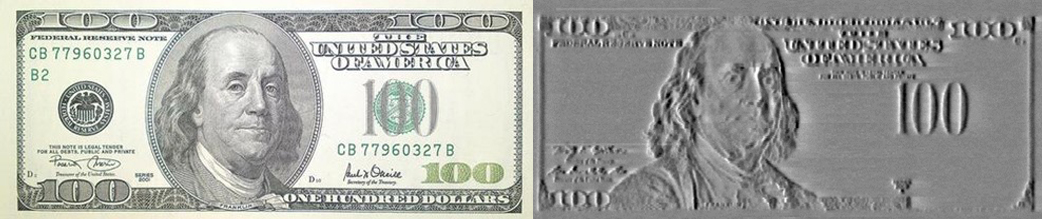

(2) Magnetic image sensor

Magnetic image sensor technology is an emerging high technology that conveniently converts magnetic signals, which are invisible to the naked eye, into image signals for easy visual observation. It lays a foundation for the transformation of magnetic signals from one-dimensional to two-dimensional, providing a convenient and fast solution to quality issues during the diversified development of magnetic products. This technology is widely used in areas like banknote sorting. With the development of the times, it is expected to mature further and be more widely used.

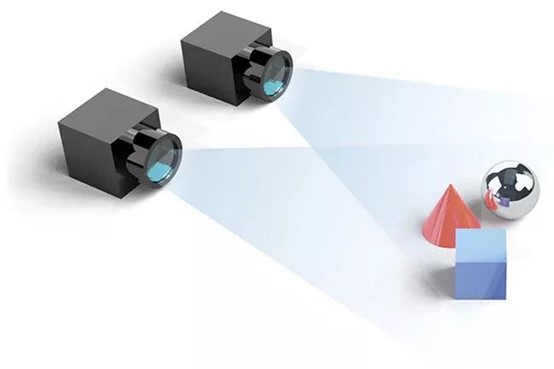

(3) Three-dimensional Imaging

Three-dimensional imaging is an intelligent, visual high technology that is based on optical imaging and integrates optical, mechanical, electrical, and computer technologies. It is primarily used for scanning the spatial shape and structure of an object to obtain its three-dimensional contour and derive the three-dimensional spatial coordinates of the points on the object's surface. With the advancement of modern inspection technology, especially with the development of laser, computer, image processing, and other high technologies, three-dimensional measurement technology has also evolved fast, and the high-speed, high-precision three-dimensional reconstruction of objects has become increasingly accurate. Due to its non-contact nature, rapid measurement, and high precision, three-dimensional measurement technology is now widely used in mechanical manufacturing and other fields.

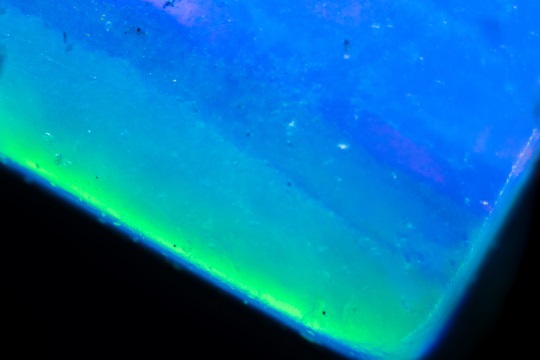

(4) Microscopic imaging

Microscopic imaging technology is primarily used as an optical inspection instrument for micro and nanoscale measurements on various precision devices and material surfaces.

Based on microscopy techniques, and combining precision Z-axis scanning modules and 3D modeling algorithms, it can perform non-contact scanning of device surfaces and create 3D surface images, enabling 3D measurement of the surface morphology of devices. The microscopic imaging technology can be used to measure and analyze surface morphology features of various products, components, and materials, including contours, defects, wear, corrosion, planarity, roughness, waviness, pore gaps, step heights, bending deformations, and machining conditions, thus facilitating high-precision detection and measurement in the microscopic field.